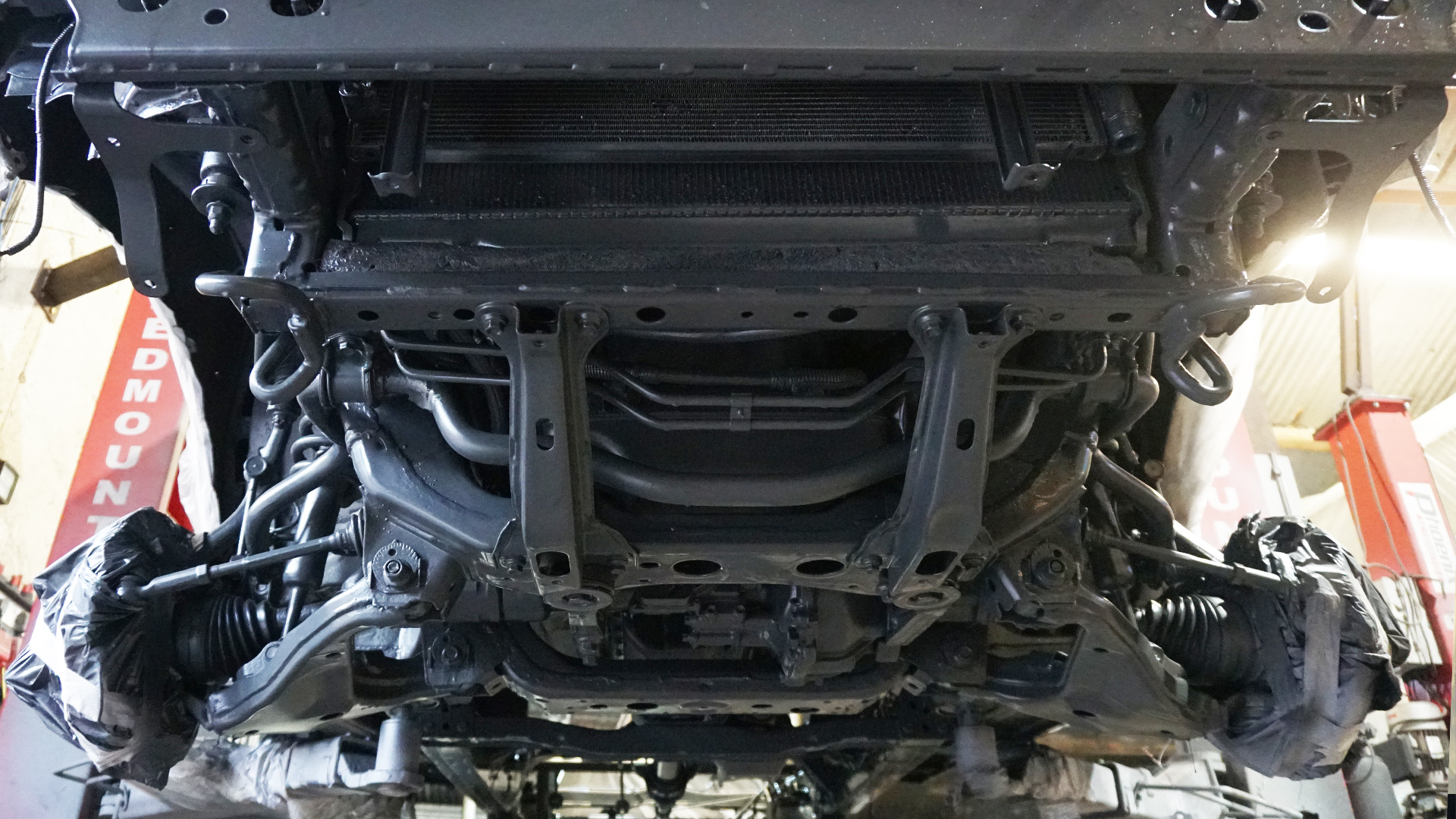

Undersealing

Protect your car’s underbody from corrosion, rust and damage with an undersealing treatment. Our unique process starts with shot blasting the underbody of your vehicle before welding and fabrication. Finally, a primer and topcoat are applied for long-lasting protection. With an undersealing treatment, you can enjoy the peace of mind knowing your car is protected from a variety of external elements and damage. We offer an industry leading undersealing package for domestic, commercial and vintage vehicles, ensuring maximum protection and adding value to your purchase. Invest in the longevity of your vehicle with Rayco Group.

Step 1: Inspection

Before we can get started, it is important to thoroughly inspect the vehicle for any obvious signs of damage, broken parts, rust or corrosion. This detailed inspection is critical in understanding the extent of the damage and will help us create a repair plan and accurate estimate of how long the treatment will take.

Step 2: Shot Blasting

Shot blasting is an effective and efficient way to remove rust and corrosion from the underneath of your vehicle. Our high-pressure system, which runs at 12 bar, is designed to be fast and cost-effective while also being environmentally friendly. We use a combination of powerful air jets and abrasive media to quickly break down the rust and corrosion, leaving a course surface that the primer will bond to.

Step 3: Welding & Fabrication

We specialize in fabricating and welding vehicle and chassis repair. Whenever possible, we employ the use of pre cut pieces in order to reduce cost and speed up the time needed for vehicle repair. Our expert team of certified welders and fabricators are highly skilled professionals who have dedicated their time and energy to ensure that your vehicle is fully repaired with the utmost quality standards.

Step 4: Engineer’s Report

An independent engineer is essential in the vehicle maintenance process, conducting a comprehensive assessment to ensure that all work performed meets the highest industry standards and complies with all safety regulations. Their expertise is invaluable in providing an unbiased evaluation, delivering professional results that meet the highest quality requirements. The report will be available on delivery of the vehicle.

Step 5: Primer

Now that the repairs have been completed and the engineer’s report is finalized, we can begin the underseal treatment. Our epoxy 97% zinc primer is equivalent to galvanising and provides superior protection against rust and corrosion, making it an ideal choice for long-term prevention. This unique material ensures that our customers can rest assured that their assets are well-protected in even the harshest of conditions.

Step 6: Topcoat

Next we apply our special 2K polyurethane topcoat, which is designed to provide outstanding protection for all types of weather conditions. This topcoat leaves a strong and durable finish that will last for years – available in both glossy and matte black. Furthermore, this topcoat provides excellent resistance to fading, chalking, and cracking making it the perfect choice for those who want long lasting protection from the elements.

Step 7: Final Inspection

Finally, our team of expert professionals thoroughly inspects every single detail of your vehicle to ensure that it is in perfect condition and meets all the necessary standards. Our meticulous attention to detail ensures that everything is as it should be, giving you complete peace of mind.

Our Products:

Our Epoxy 97% Zinc Primer

Our 2K Polyurethane Topcoat